Lo mkhiqizo wengezwe ngempumelelo ekalishini!

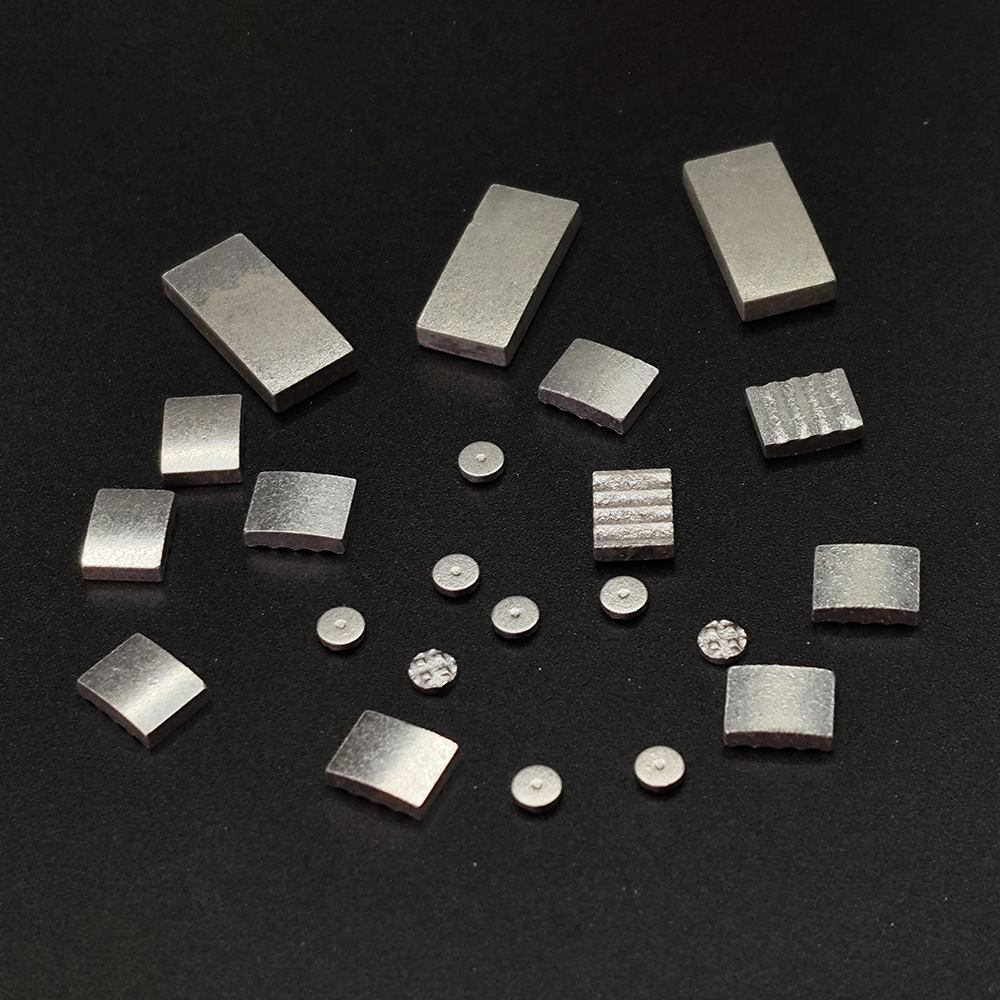

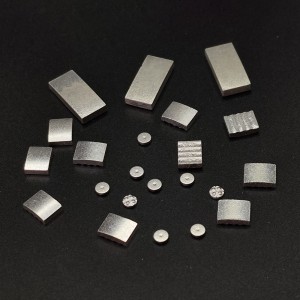

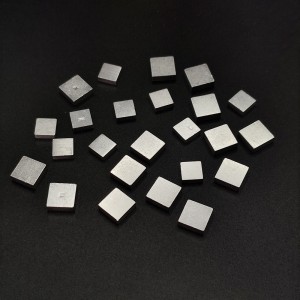

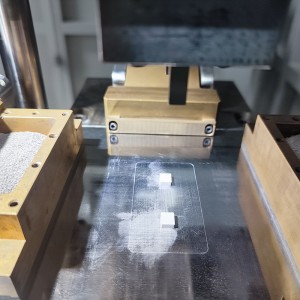

I-Silver Tungsten (AgW)

Oxhumana nabo be-tungsten esiliva bayingxenye kagesi evamile eyenziwe ngenhlanganisela yesiliva (Ag) ne-tungsten (W).Isiliva sinokusebenza kahle kukagesi kanye ne-conductivity kagesi, kuyilapho i-tungsten inephuzu eliphezulu lokuncibilika, ubulukhuni obuphezulu nokumelana nokugqoka.Ngokuhlanganisa isiliva ne-tungsten, othintana nabo be-tungsten esiliva banikeza ukuthintana kukagesi okuzinzile nokuqina.Oxhumana nabo be-tungsten esiliva bavame ukusetshenziswa ekusetshenzisweni kwamanje okuphezulu, izinga lokushisa eliphezulu kanye nezicelo zomthwalo ophezulu ezifana nemishini kagesi, ama-circuit breaker kanye nama-resistors.Banokuhamba kahle kukagesi, ukumelana nokuxhumana okuphansi kanye nokumelana nokugqoka okuhle kakhulu, futhi bangagcina ukuxhumana okuhle kukagesi futhi basebenze ngokuzinzile, kuyilapho bekwazi ukumelana nama-arcs athile kanye nokushisa okuphezulu.Ngamafuphi, othintana nabo besiliva be-tungsten yizinto ze-alloy ezakhiwe ngesiliva ne-tungsten, ezinokusebenza kahle kukagesi, ukuqhutshwa kukagesi, ukumelana nokugqoka kanye nokumelana nokushisa okuphezulu.Zisetshenziswa kabanzi embonini kagesi ukuze zinikeze ukuxhumana okuthembekile kagesi nokusebenza okuzinzile kokusebenza.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HB) |

| (g/cm3) | (IACS) | |||

| AgW50 | 50±2.0 | 13.2 | 57 | 130 |

| AgW65 | 35±2.0 | 14.6 | 50 | 160 |

| AgW75 | 25±2.0 | 15.4 | 41 | 200 |

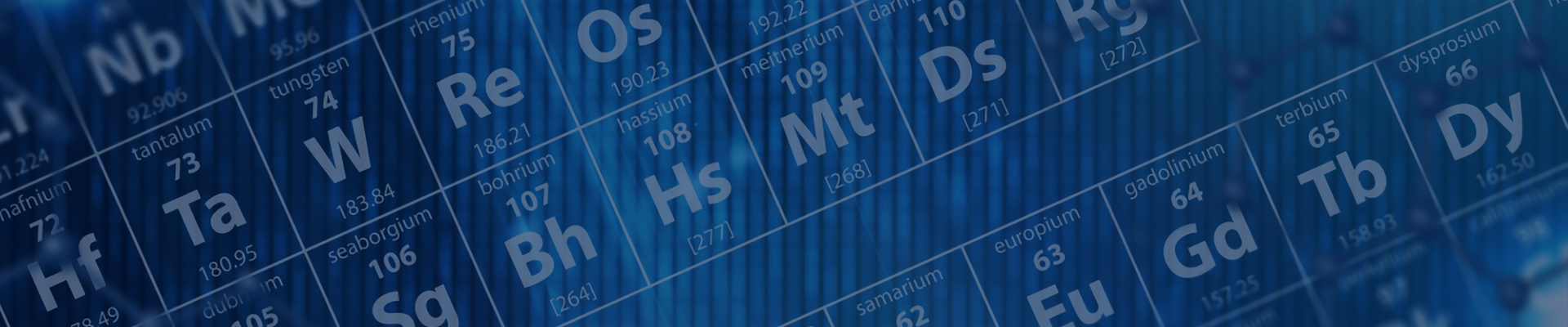

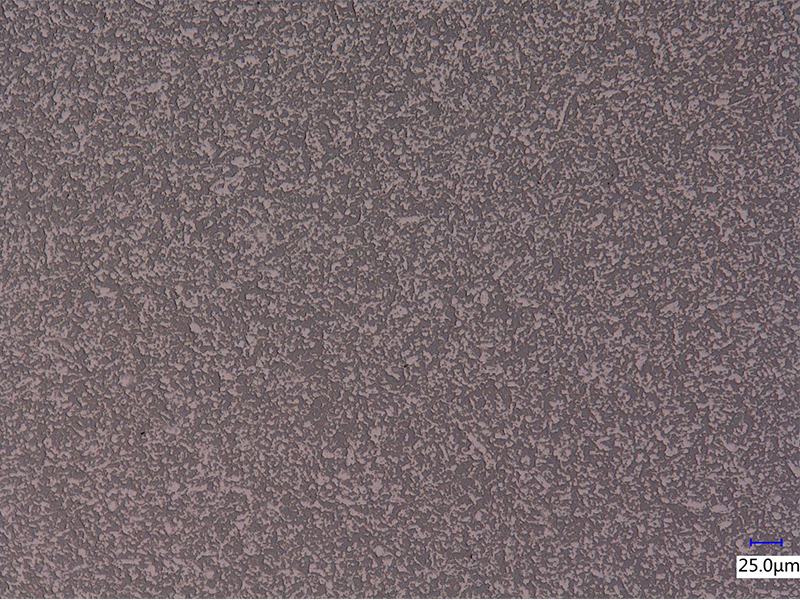

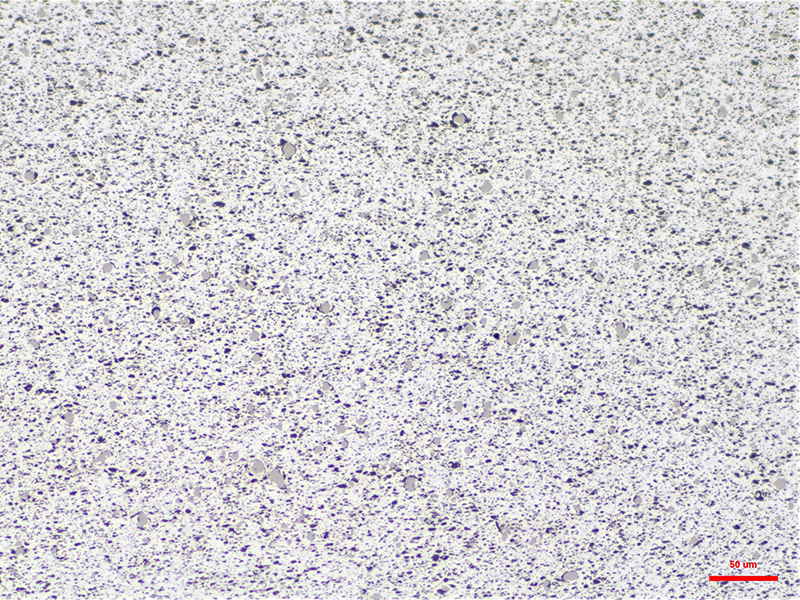

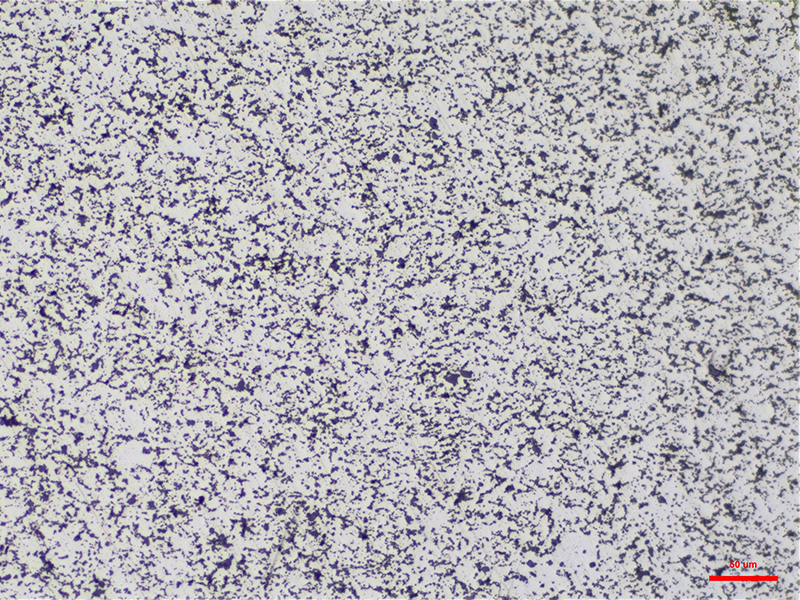

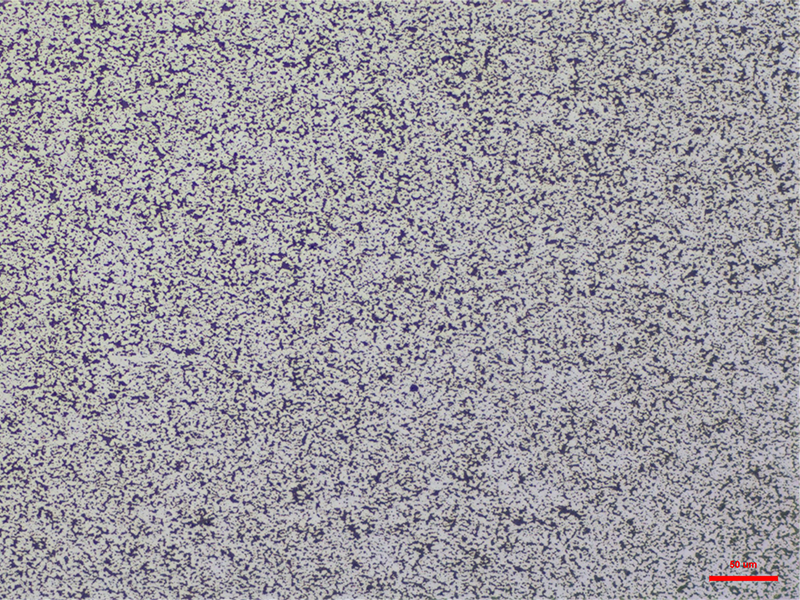

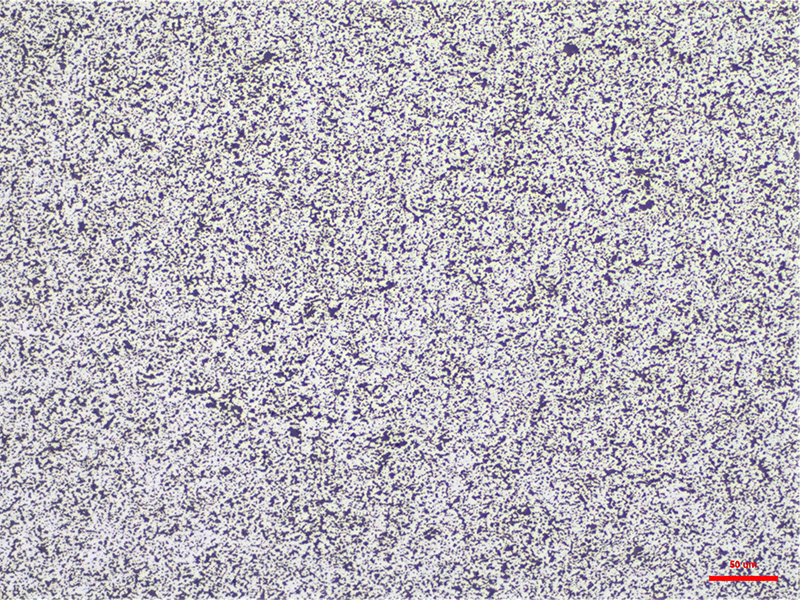

Isibonisi se-Metallographic

I-AgW(50) 200X

I-AgW(65) 200X

I-AgW(75) 200X

I-Silver Tungsten Carbide (AgWC)

Oxhumana nabo be-tungsten carbide esiliva bayinto ekhethekile yokuxhumana eyinhlanganisela yesiliva (Ag) ne-tungsten carbide (WC).Isiliva sinokusebenza kahle kukagesi kanye nokuhamba kukagesi, kuyilapho i-tungsten carbide inobulukhuni obuphezulu, indawo ephakeme yokuncibilika kanye nokumelana nokugqoka.Oxhumana nabo besiliva be-tungsten carbide banokuqina okuphezulu nokumelana nokugqoka, futhi bangagcina ukuxhumana okuzinzile kukagesi isikhathi eside ngaphansi komthwalo ophezulu nezimo zokushisa eziphezulu.Ukuqina kwe-tungsten carbide kunikeza abathintwayo ukuzinza okuhle kwemishini ngokumelene nama-voltage aphezulu, imisinga ephezulu kanye nokusebenza kokushintsha njalo.I-conductivity yokuxhumana kwe-silver tungsten carbide ingcono kunokuxhumana okuhlanzekile kwesiliva, ikakhulukazi ekushiseni okuphezulu nomthwalo ophezulu.Oxhumana nabo be-tungsten besiliva be-carbide banikeza ukumelana okuphansi kokuxhumana nokusebenza kukagesi okuzinzile.Ngakho-ke, impahla yokuxhumana ye-tungsten carbide yesiliva iyisinqumo sokusebenza okuphezulu futhi isetshenziswa kabanzi emishinini kagesi edinga ukumelana nokugqoka okuphezulu, izinga lokushisa eliphezulu nomthwalo ophezulu, njengokushintshwa, ama-relay kanye nama-circuit breakers, njll. Banikeza ukuxhumana okuthembekile kagesi kanye nobude obude. ukuphila kwezinhlobonhlobo zezindawo zokusebenza ezinokhahlo.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| AgWC30 | 70±3 | 11.35 | 59 | 125 |

| AgWC40 | 60±3 | 11.8 | 50 | 140 |

| AgWC50 | 50±3 | 12.2 | 40 | 255 |

| AgWC60 | 40±3 | 12.8 | 35 | 260 |

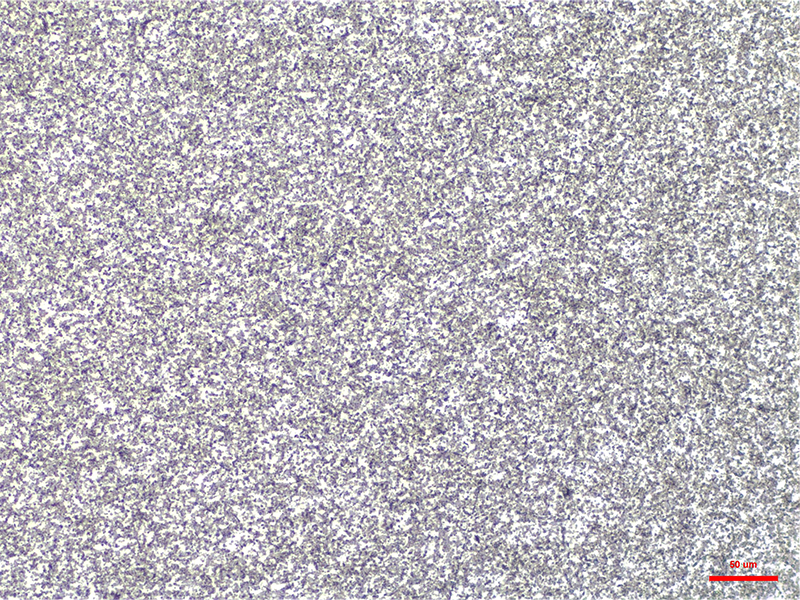

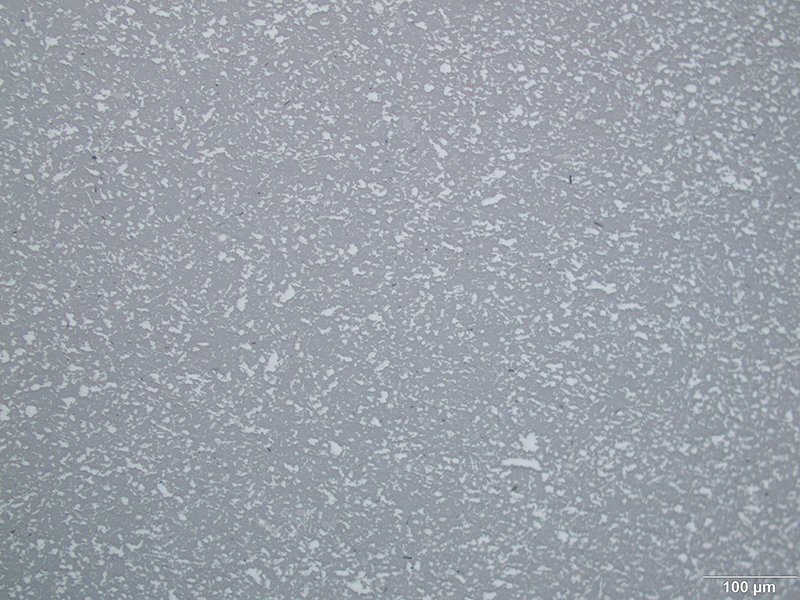

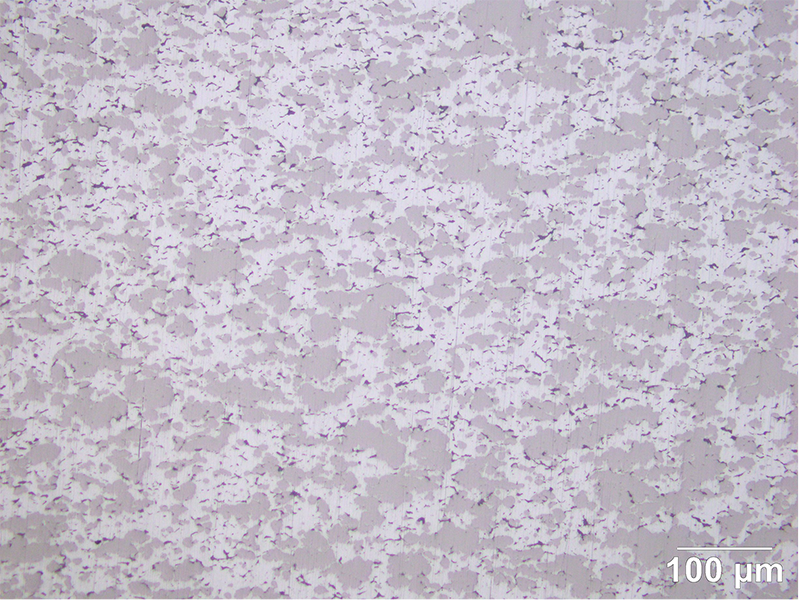

Isibonisi se-Metallographic

I-AgWC(30) 200×

I-AgWC(40)

I-AgWC(50)

I-Silver Tungsten Carbide Graphite (AgWCC)

I-Silver tungsten carbide graphite contacts iyinto yokuxhumana evame ukusetshenziswa, ehlanganisa izinto ezimbili, isiliva (Ag) ne-tungsten carbide (WC), ene-graphite eyengeziwe nezinye izithasiselo.Isiliva sinokusebenza kahle kukagesi kanye ne-electrical conductivity, i-tungsten carbide inobunzima obuphezulu nokumelana nokugqoka, kanti i-graphite inezinto ezinhle zokuzigcoba.Oxhumana nabo be-Silver tungsten carbide graphite banezakhiwo ezinhle kakhulu zikagesi nezemishini.I-conductivity ephezulu yesiliva iqinisekisa ikhono elihle le-conductivity yamanje yabathintana nabo, futhi ukuqina okuphezulu nokumelana nokugqoka kwe-tungsten carbide kunikeza oxhumana nabo impilo ende yesevisi.Ngaphezu kwalokho, izakhiwo zokuzigcoba ze-graphite zinciphisa ukungqubuzana nokugqoka kwabathintana nabo, ukuthuthukisa ukuzinza nokuthembeka kwabo.Oxhumana nabo be-Silver tungsten carbide graphite balungele ukulayisha okuphezulu kanye nezinhlelo zokusebenza zokushintsha njalo, njengama-relay, ama-circuit breaker, ama-motor namaswishi emishini kagesi.Bangasebenza ezindaweni ezinzima ezifana nezinga lokushisa eliphezulu kanye nomswakama ophezulu, futhi babe nokumelana nokugqwala okuhle nokumelana nokushisa.Sekukonke, othintana nabo besiliva be-tungsten carbide graphite bayinto yokuxhumana enezakhiwo ezinhle zikagesi, ukumelana nokugqoka nokuzinza.Banikeza ukuxhumana okuthembekile kagesi futhi banikeze ukusebenza okuzinzile isikhathi eside ngaphansi kwezimo zokusebenza ezinzima.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| I-AgWC12C3 | 85±1.0 | 9.6 | 60 | 56 |

| I-AgWC22C3 | 75±1.0 | 10 | 58 | 66 |

| AgWC27C3 | 70±1.0 | 10.05 | 41 | 68 |

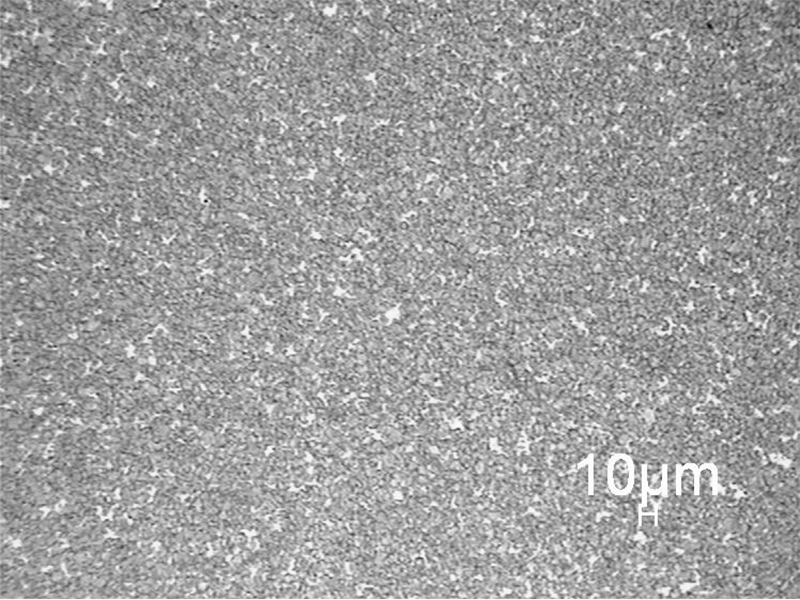

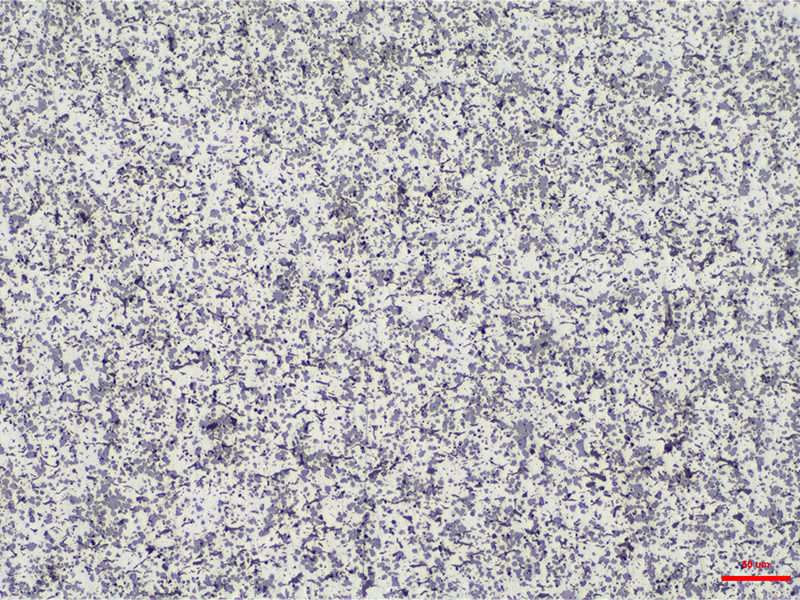

Isibonisi se-Metallographic

I-AgWC12C3 200X

I-AgWC22C3

AgWC27C3

I-Silver nickel Graphite (AgNiC)

I-Silver nickel graphite contact material iyinto evamile yokuxhumana, equkethe izingxenye ezintathu: isiliva (Ag), i-nickel (Ni) ne-graphite (C).Ine-conductivity kagesi enhle kakhulu, ukumelana nokugqoka kanye nokuzinza okuphezulu kwezinga lokushisa.I-Silver nickel graphite contact material inezici ezilandelayo: I-conductivity kagesi enhle kakhulu: Isiliva ine-conductivity kagesi enhle kakhulu futhi inganikeza ukumelana okuphansi kanye ne-conductivity ephezulu yamanje, kuyilapho ukungezwa kwe-nickel ne-graphite kungathuthukisa ukuqhutshwa kukagesi futhi kunciphise ukuminyana kwamanje koxhumana nabo.Ukumelana nokugqoka: Ukwengezwa kwe-nickel ne-graphite kwandisa ubulukhuni kanye nokuthambisa koxhumana nabo, okunganciphisa ukungqubuzana nokuguga futhi kunwebe impilo yesevisi yabathintwayo.Ukuzinza okuphezulu kwezinga lokushisa: I-Silver nickel graphite contact material ine-high melting point kanye nokuzinza kwe-thermal, futhi ingagcina ukuhanjiswa kukagesi okuzinzile kanye nokuthembeka kokuxhumana ezindaweni zokushisa okuphezulu.Ukumelana ne-oxidation: Ukwengezwa kwe-nickel ne-graphite kungathuthukisa ukumelana ne-oxidation koxhumana nabo, kubambezele ijubane le-oxidation labathintana nabo, futhi kunciphise ukushintshwa kokumelana koxhumana nabo.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| I-AgNi15C4 | 95.5±1.5 | 9 | 33 | 65 |

| I-AgNi25C2 | 71.5±2 | 9.2 | 53 | 60 |

| I-AgNi30C3 | 66.5±1.5 | 8.9 | 50 | 60 |

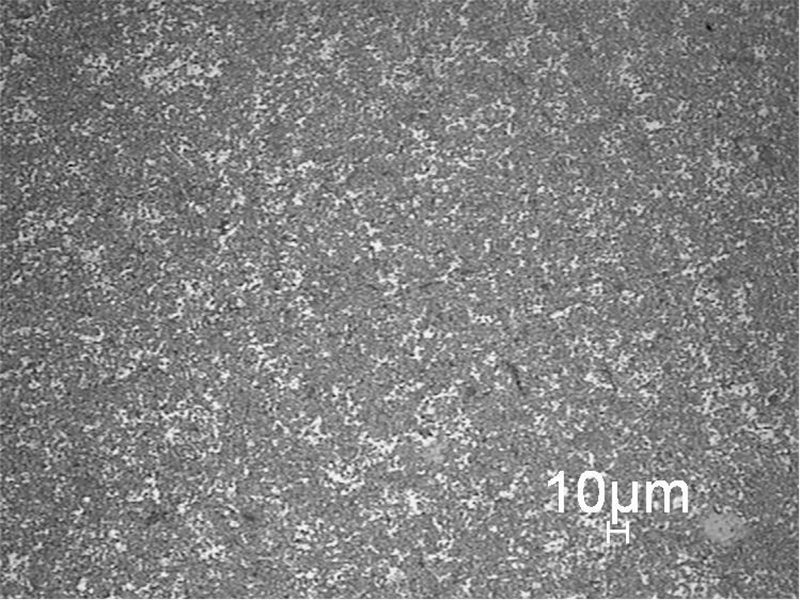

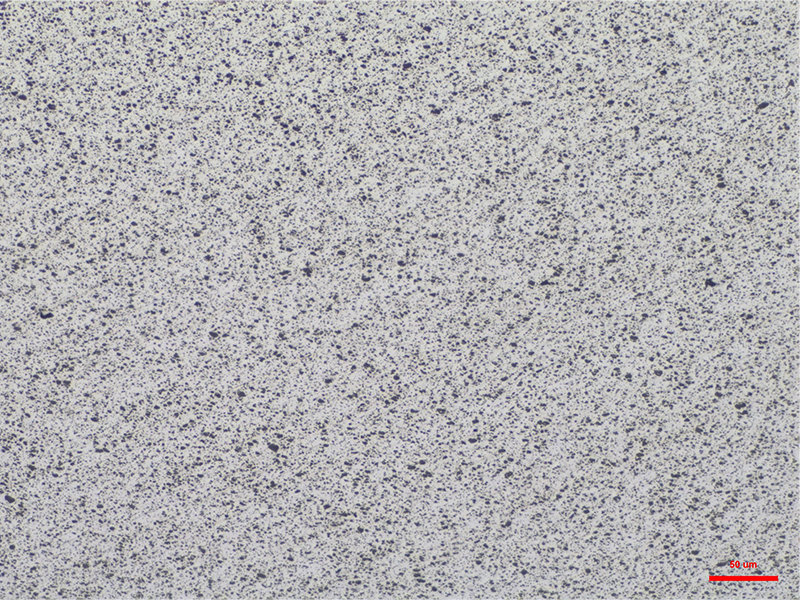

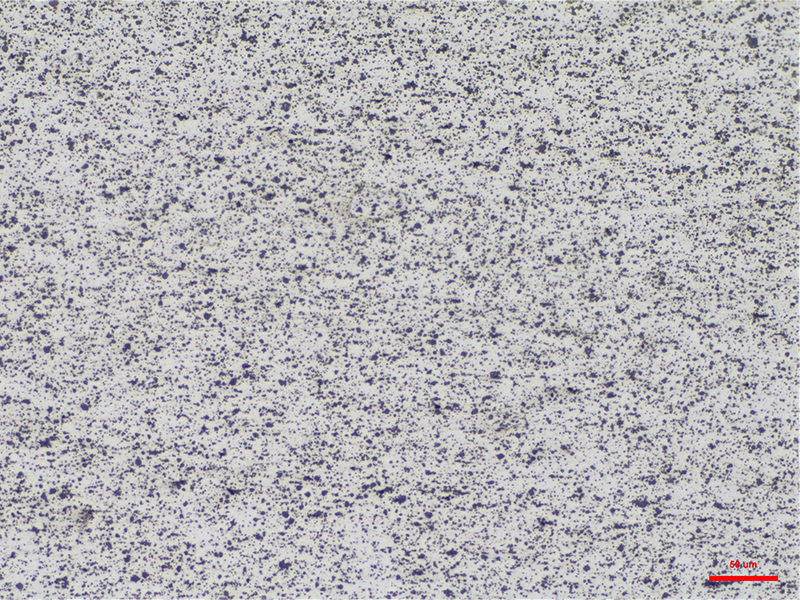

Isibonisi se-Metallographic

I-AgNi15C4 200X

I-AgNi25C2

I-Silver Graphite (AgC)

I-graphite yesiliva iyinhlanganisela yesiliva (Ag) ne-graphite (ikhabhoni).Ngenxa yezindawo zayo eziyingqayizivele, isetshenziswa kakhulu emikhakheni ehlukahlukene.I-graphite yesiliva isiphenduke into evamile yokuxhumana enganyakazi futhi ijwayele ukubhangqwa ne-AgW noma i-AgWC.Iningi le-circuit breaker kanye nama-switch grade aqukethe i-95% kuya ku-97% yesiliva.I-Silver graphite inezici eziphakeme zokulwa nokushisela ngakho-ke iyisinqumo esihle uma i-tack welding iyinkinga.Ngaphezu kwalokho, i-graphite yesiliva inokusebenza okuhle kakhulu kukagesi ngenxa yokuqukethwe kwesiliva okuphezulu ngokujwayelekile nangenxa yegesi encishisiwe eyenziwe yi-graphite.Into ethambile kakhulu kune-tungsten esiliva noma i-tungsten carbide esiliva, i-graphite eyisiliva inezinga eliphezulu lokuguguleka.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| AgC3 | 97±0.5 | 9.1 | 78 | 42 |

| I-AgC4 | 96±0.7 | 8.8 | 75 | 42 |

| AgC5 | 95±0.8 | 8.6 | 69 | 42 |

Isibonisi se-Metallographic

I-AgC(4) 200X

I-Silver tin oxide (AgSnO2)

I-Silver tin Oxide ine-conductivity kagesi enhle futhi imelana nokugqoka.Izinto zokuxhumana ze-Silver tin oxide zinezici ezilandelayo: I-conductivity kagesi enhle kakhulu: Isiliva sinokusebenza okuhle kakhulu kukagesi futhi singanikeza ukumelana okuphansi kanye nokusebenza okuphezulu kwamanje.Ukumelana nokugqoka: Izinhlayiya ezinhle ze-tin oxide ezakheka lapho i-tin oxide ethintwayo ingadlala indima ekugcobiseni nasekunciphiseni ukungqubuzana, ukuze othintana naye abe nokungagugi kahle.Ukuzinza: Izinto zokuxhumana ze-tin oxide esiliva zizinzile futhi zithembekile ngaphansi kwezimo ezijwayelekile zokusebenza futhi zinganikeza ukuthintana kukagesi okuzinzile kwesikhathi eside.Ukumelana nokugqwala: Okuthintana ne-Silver tin oxide kunokumelana nokugqwala okuhle futhi kungasebenza endaweni enomswakama kanye negqwala.I-Silver tin oxide powder impahla ifanele izixhumi ze-AC eziyi-100-1000A

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| I-AgSnO2(10) | 90±1 | 9.6 | 70 | 75 |

| I-AgSnO2(12) | 88±1 | 9.5 | 65 | 80 |

Isibonisi se-Metallographic

I-AgSnO2(10)

I-AgSnO2(12)

I-Silver Zinc Oxide (AgZnO)

I-Silver zinc oxide (Ag-ZnO) ukuthintana iyinto yokuxhumana evame ukusetshenziswa, okuyinhlanganisela yesiliva (Ag) ne-zinc oxide (ZnO).Isiliva sinokusebenza kahle kukagesi kanye ne-conductivity kagesi, kuyilapho i-zinc oxide ine-resistivity ephezulu kanye nokumelana nokushisa okuphezulu.Oxhumana nabo be-zinc oxide esiliva banokuzinza okuhle nokumelana nokugqoka ngaphansi kwezinga lokushisa eliphezulu nezimo eziphezulu zamanje.Ukwengezwa kwe-zinc oxide kukhulisa ubulukhuni nokumelana nokugqokwa kwezinto zokuthintana, kuyilapho kuhlinzeka ngezinga elithile le-arc nokucisha ukushisa.Oxhumana nabo be-zinc oxide esiliva banokumelana okuphansi kokuxhumana kanye nezakhiwo zikagesi ezinhle kakhulu, okuhlinzeka ngokuthinta okuthembekile kagesi ngesikhathi sokushintshwa.Zisetshenziswa kakhulu ekushintsheni, ekudluliseleni kanye nama-circuit breaker emishini kagesi ehlukahlukene, futhi ingahlangabezana nezidingo zomthwalo omkhulu nokushintsha njalo.Ngaphezu kwalokho, ukuxhumana kwe-zinc oxide yesiliva nakho kunokumelana okuhle kwe-oxidation, okungandisa impilo yesevisi yothintana naye.Zifanele ukusetshenziswa ngaphansi kwezimo ezihlukahlukene zemvelo, okuhlanganisa izinga lokushisa eliphezulu, umswakama ophezulu kanye nezindawo zokusebenza ezinzima.Sekukonke, othintana nabo be-zinc oxide esiliva bayinto yokuxhumana evame ukusetshenziswa enezinto ezinhle zikagesi, ukumelana nokugqoka nokuzinza.Badlala ukuxhumeka kukagesi okubalulekile kanye nemisebenzi yokushintsha imishini kagesi, futhi bangahlangabezana nezimo ezihlukahlukene zokusebenza ezinzima.

| Igama lomkhiqizo | I-Ag Component(wt%) | Ukuminyana | I-Conductivity | Ukuqina (HV) |

| (g/cm3) | (IACS) | |||

| I-AgZnO(8) | 92 | 9.4 | 69 | 65 |

| 56 | ||||

| I-AgZnO(10) | 90 | 9.3 | 66 | 65 |

| 52 | ||||

| I-AgZnO(12) | 88 | 9.25 | 63 | 70 |

| 9.1 | 50 | |||

| I-AgZnO(14) | 86 | 9.15 | 60 | 70 |

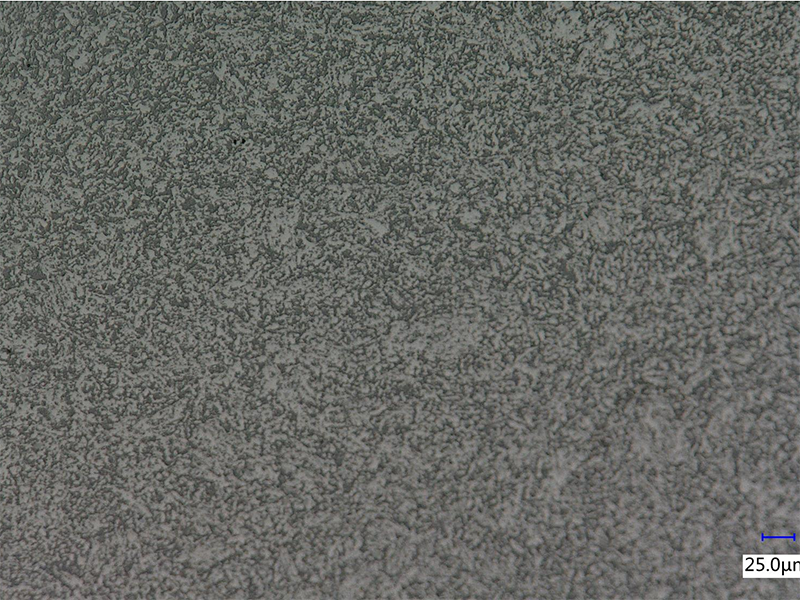

Isibonisi se-Metallographic

I-AgZnO(12) 200X

I-AgZnO(14) 200X